P.I.N.D.- Particle Impact Noise Detection

Vibration, Shock and Acoustic means are used to ensure the reliability of electronic components

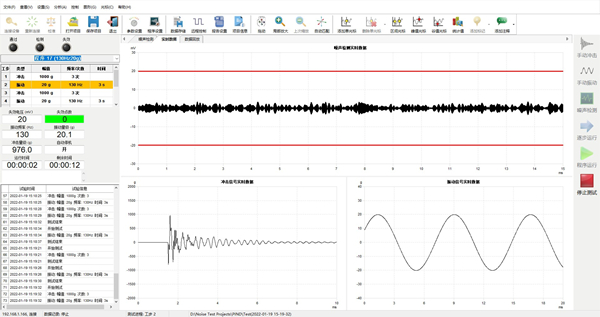

PD SERIES USER INTERFACE

Our PD series particle impact noise detector can detect loose particles moving freely in the cavities of electronic components including relays, transistors, hybrid circuits, integrated circuits and switches,etc. These particles are often the potential cause of short circuits and serious system operation failures.

The shaker is used to excite loose particles in the cavity of the component. The energy of the particles striking the cavity housing is converted into a wide-band pressure wave, which passes through the housing and is detected by a sensitive ultrasonic sensor mounted on the test equipment. In order to ensure that the particles can make accurate impact motion, we use sensors to provide feedback vibration signals to the controller, and through the controller to control the closed-loop shaker work.

PD Series Particle Impact Noise Detector - ADVANCED TECHNOLOGY THAT'S EASY TO USE

Our PD series features packaging and is the most advanced system available today. Combining sensors that monitor and display the shaker motion with computer control to correct for any changes in test conditions, Our PIND test system generates accurate and repeatable test conditions. Its ultra-sensitive, ultrasonic (155 KHz) sensor with multiple crystals can detect particles as lighter than 0.16 micrograms impacting the package cavity.

The multiple computer technology not only controls the motion but also allows the user to program the motion including both shock and vibration at the precise amplitude and timing to simulate the whole range of testing requirements. The operator simply needs to input the desired shock amplitude and duration, or the vibration frequency, and the PIND system can automatically calculate the appropriate frequency and drive the shaker to produce the appropriate motion.

You will be surprised by the quick and easy way of programming and operation of PD series PIND equipment. The system functions can fully meet the requirements of relevant PIND test specifications.

PROGRAMMABLE SOFTWARE FOR MORE VERSATILITY

Using our software developed entirely based on engineering applications, PIND 's operating system is customized to meet your specific testing requirements. Through Windows programming, greatly facilitate the use of operators.

System with a low-pass filtering feature will automatically reduce the vibration amplitude to perform low-frequency tests up to 25 Hz. Such test objects mainly include relays, hybrid circuits and components that need to be carefully tested. If other testing requirements, you can modify the parameter settings to reality.

UNIQUE FEATURES OFFER CONVENIENCE AND FLEXIBILITY

Whether you're testing electronic components for cardiac pacemakers, manned spacecraft or undersea cables, you'll enjoy the convenience and flexibility of the special features which set our system apart from any other PIND test system. Based on years of after-sales maintenance experience of mainstream PIND products, our technical developers ensure that the detection sensitivity of PD series particle collision noise detector is consistent with the current mainstream PIND equipment standards, so as to ensure the reference and traceability of customer test results to the maximum extent!

- PD series system easily exceeds the requirements of all military standards for PIND testing (QJ2863, QJ789A, GJB65B, GJB128A, GJB548B, GJB360B, GJB2888A).

- Imbedded sensors that monitor and display the actual shaker motion with computer control to correct for any changes in test conditions, the PD series system generates accurate and repeatable test conditions.

- The unique PD series PIND shaker creates accurate “Active Shocks” with adjustable shock levels by controlling the velocity of the shaker head and correcting for device differences prior to shock.

- The PD series system offers a low profile, low stray magnetic field design that eliminates any need for an expensive special test bench, required for conventional shakers with external shock fixtures.

- The PD series system is an all-DIGITAL system with no knobs or screws to adjust. It is fully programmable to your own specifications or as required by military standard. Since everything is generated by the computer, the user can create different amplitudes, frequencies, and durations. There is future expansion to more complex motion environments including Random Vibration and advanced Shock conditions.

- Graphical interface display based on Windows software

- Real-time display of noise, shock and vibration time-domain signals to maximize the restoration of Real Waveforms for convenient observation and judgment

- Support current mainstream Windows OS

- Real-time storage of data and waveforms, playback of the entire test process

- Reports can be generated automatically in Word, Excel and PDF formats. The data is saved in Excel for subsequent analysis

- Standard Quick Start and Stop physical button is to enhance equipment security

- Optional auxiliary accessories such as foot pedal and shortcut key board are available for easy operation

- Calibration output value can be adjusted according to the quality of the product to be tested

- Software built-in 19 standard procedures, other programs can be programmed and saved

- Through special interfaces and protocols, PD series PIND can be integrated with automatic equipment such as mechanical arm to achieve PIND detection automation

Key Feature

Introduction

Introduction